Pick & Place Automation

Browse Services

Our current processes

- Solder Paste printing – DEK240 & Speedprint SP200

- SMT Pick-&-Place QSP-2 Plus

- SehoFlowstart 4036 1.7 & Unifab 30I/R

- 3D AOI – Mirtec MV-2BTL

- XYtronic LF-8800 & JCB6040 rework stations

- Blundell CMS wave solder

Pick & Place

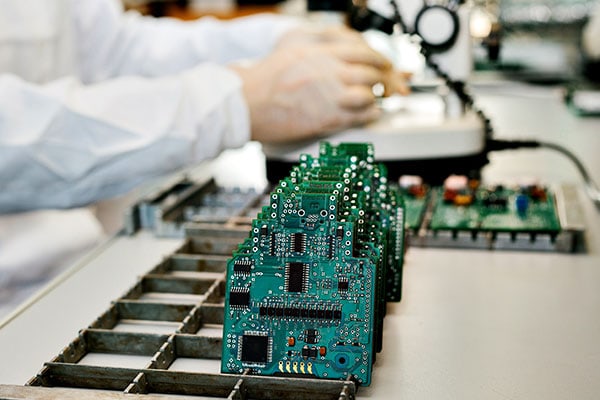

Alpha has a robust knowledge of placing surfacemount components and take on many challenging designs. Our surfacemount automated pick and place production cell consists of a Speedprint SP200 solder paste machine along with Genesis 58 solder stencils. Our pick and place machine is a Quad QSP-2Plus which is duel headed with a total of 8 suction nozzles. It can hold up to 144x8mm component feeders and our standard hot air reflow is a Seho Flowstar 4036 1.7, 8 zone, with a max. width of 350mm. We also have the option of Infrared reflow by using our UniFab Quantum 30 which has a max. width of 260mm.

For inspection we use a mix of manual, ‘Supereyes’ magnification and Automated Optical Inspection (AOI) machine Mirtec MV-2BTL.

We are ISO 9001:2008 approved and all our client products are assembled and inspected to meet the industry standard IPC-A-610 prior to dispatch.

Our Specialisms

- Pick-and-Place of Surface Mount components down to 0201

- Conventional Through-Hole manual and wave solder capability

- FR4 and Aluminium substrates

- Conformal coating and Encapsulation

- ISO9001 Accreditation

- All workmanship carried out to IPC J-STD

- All inspections carried out to PCB specific IPC-A-610 and wiring specific IPC-A-620 quality control

Combining our full range of supply chain management, manufacturing and test capabilities allows Alpha Electronics to provide you with fast, efficient, and cost-effective turnkey solutions tailored to your production needs.

Our turnkey assembly services encompass all aspect of the project including the procurement of components, manufacturing the PCB and the Box Build Assembly. Final test solutions and packaging then complete your assembly ready for shipment.

As the single point of contact, we will manage your requirement, source parts, and liaise with suppliers to deliver the end product – allowing you to concentrate on your core business of selling it instead.

Offices

Our manufactured products sold internationally