Potting & Conformal Coating

Browse Services

What are conformal coating characteristics?

Potting & Conformal Coating

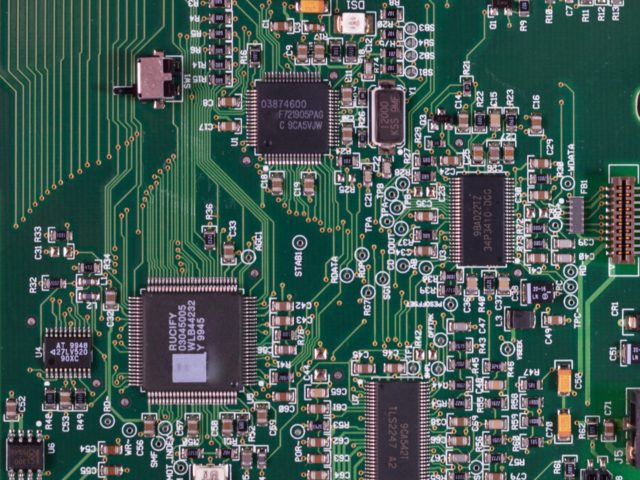

Alpha Electronics Manufacturing can produce a variety of coating and encapsulation processes of pcb’s, connectors and boxes for their quality assured electronics solutions to meet with your specific requirements. Conformal coatings protect pcb’s from moisture and contaminants, preventing short circuits and corrosion of conductors and solder joints. They also minimise dendritic growth and the electromigration of metal between conductors. The use of conformal coatings protects circuits and components from abrasion and solvents. Stress relief can be provided, as well as protection of the insulation resistance of the circuit.

Potting and conformal coating can produce protection from environmental hazards, Increased reliability and resilience.

Specializations

Potting and conformal coating aid to prevent circuits from failing in harsh environments or from vibrations and other potentially damaging uses. It increases the electrical performance of a circuit board through shielding and both methods can be effective when used in the right situation. Potting should be used for impact resistance and can also be used to obscure identification of the components used within a design.

Alpha’s preferred material to use for conformal coating is an Acrylic coating – Humiseal 1B73 which is applied by either brushing or spraying under our BV200H-D Bench Vent extraction hood.

Parylene coating can be offered by using a 3rd party specialised in the application. Parylene is a polymer coating used for protecting various circuits in the Medical and Aerospace industries.

Offices

Our manufactured products sold internationally